|

Technology > Laser cutting

3 laser systems

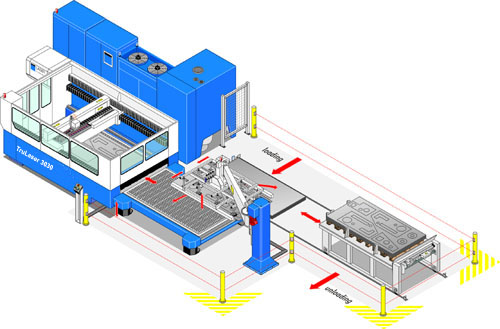

Laser TRUMPF TruLaser 3030 FIBER - 6000w

Quick machines for all cutting purposes: TruLaser 3030 fiber. These machines stand out thanks to their high flexibility and productivity: they allow to maximize the performances when cutting metal sheets of all thicknesses.

|

|

|

Laser TRUMPF 3030 - 4000W

Main characteristics:

|

Laser TRUMPF 3040 - 5000W

Main characteristics:

Any metallic material can be processed with the laser cutter; the workable thickness varies depending on the composition of the material itself:

|

||||||

|

||||||

|

|

Automation The principal feature of the automation concept of the 2D systems for laser cutting lays in their modularity. The large mix of automation components allows meeting any client’s requirements. From semi-automatic loading to a fully automated process.

|

LIFT MASTER COMPACT |

LIFT MASTER |