|

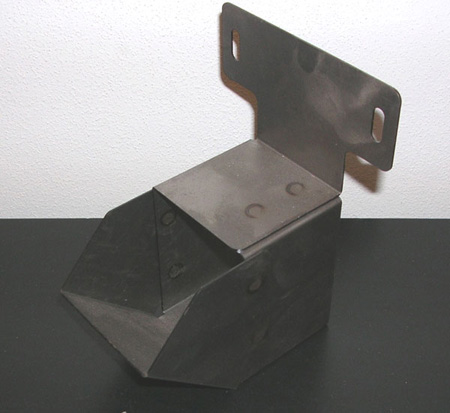

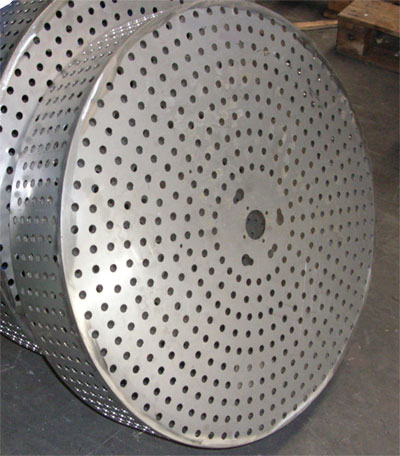

Production > Welding and spot welding

Our team consists of personnel specialised in welding and electric spot welding materials such as iron AISI 304-316 stainless steel and aluminium, using MIG, TIG and SMAW processes.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MIG-MAG WELDING

The gas metal arc welding process is widely used for high productivity and for its ability to be applied to robotic automation systems. It is an autogenous welding process in which the arc strikes between the workpiece and the filler wire. The wire feeding device keeps on feeding the melted material. Protection is supplied directly on to the melted material by an inert shielding gas.

The advantages with these procedures are many:

All types of ferrous and non-ferrous materials can be welded

High quality welding

High productivity

TIG WELDING

TIG welding is not very high in productivity and is used for small thicknesses. Depending on the material to be welded the TIG can be used in direct currents as well as in alternating currents; all types of metals and non-metals can be welded using a filler rod or even, thanks to an arc with a greater energy concentration, putting the two pieces to weld side by side without using any filler rod.